Introduction:

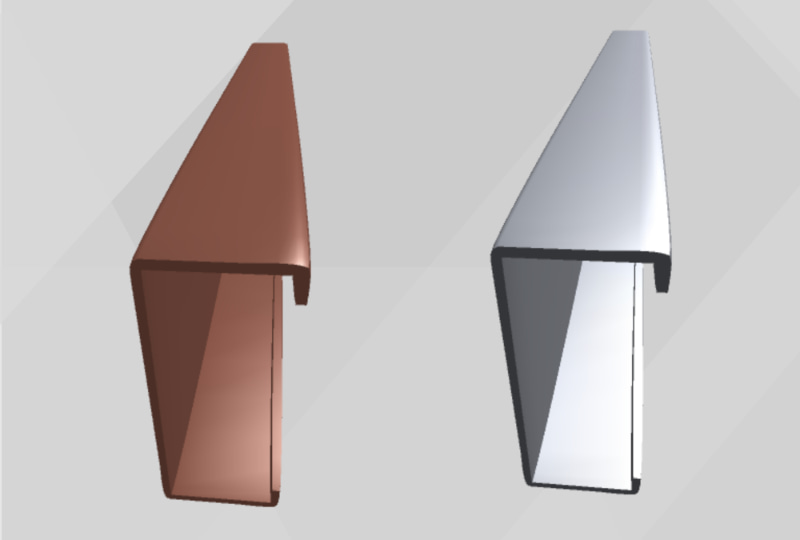

When selecting the right building materials for construction projects, the type of C-Purlins used is critical in ensuring structural integrity and durability. In this blog, we will look at the benefits of using Galvanized C-Purlins over traditional Black Iron C-Purlins, emphasizing why Galvanized Purlins are a better option for construction applications.

Enhanced Corrosion Resistance of Galvanized C-Purlins:

One of the primary benefits of galvanized Purlins is their exceptional corrosion resistance. Galvanization is the process of coating steel with a layer of zinc, creating a protective barrier against rust and corrosion. Black Iron C-Purlins, on the other hand, lack this protective coating, making them more prone to rust and degradation over time. Galvanized Purlins have a longer lifespan, lowering maintenance costs and ensuring the building’s structural integrity.

Increased Durability:

In terms of durability, Galvanized C-Purlins perform better than Black Iron C-Purlins. Galvanized Purlins have an additional layer of defense in the form of the zinc coating, which makes them extremely resilient to environmental elements like moisture, humidity, and extreme weather conditions. Because of their durability, the purlins and the structures they support last longer and require fewer replacements or repairs.

Cost-effectiveness of Galvanized C-Purlins:

Galvanized Purlins may cost a little more up front than Black Iron C-Purlins, but they provide substantial long-term cost savings. Galvanized Purlins’ resistance to corrosion and durability lead to decreased maintenance and replacement costs over time. Galvanized Purlins’ light weight makes transportation and installation easier and reduces labor and logistical costs during the construction process.

Improved Aesthetic Appeal:

Due to the zinc coating, galvanized Purlins have an aesthetically pleasing finish that gives the entire structure a tidy and professional look. The more rugged and unfinished appearance of Black Iron C-Purlins, on the other hand, may not be preferred in some architectural designs or projects that call for an aesthetically pleasing finish.

Environmental Friendliness:

Galvanized Purlins are an environmentally friendly building material. When compared to Black Iron C-Purlins, which may need replacement frequently, Galvanized Purlins have a longer lifespan and generate less waste due to the use of zinc, a recyclable material. By choosing galvanized Purlins, you can support environmentally friendly building practices while preserving structural integrity.

Conclusion:

Galvanized C-Purlins offer several advantages over Black Iron C-Purlins, making them a superior choice for construction projects. The enhanced corrosion resistance, increased durability, cost-effectiveness, improved aesthetic appeal, and environmental friendliness of Galvanized Purlins make them a reliable and long-lasting solution. By choosing Galvanized Purlins, you can ensure the longevity, structural integrity, and visual appeal of your construction projects while minimizing maintenance costs and promoting sustainability.

When it comes to Galvanized C-Purlins don’t forget to contact us as a direct dealer of JEA Steel Industries, Inc. a well-known manufacturer of standard galvanized steel in the Philippines.

For concerns and inquiries, you may send your requirements to info@metalframings.com